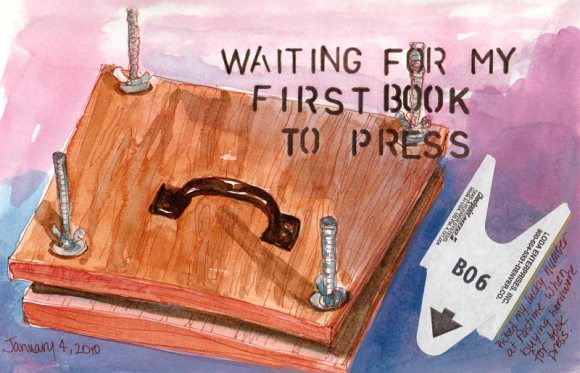

I made a book press as part of the process of learning to bind my own sketchbook. This of course required a trip to the wonderful Pastime Hardware store. I was so excited that the ticket I pulled from the little red take-a-number thingee for the helpful hardware guy (or in this case gal) had both my initial and my birth month/”lucky” number on it so I saved it for posterity in my sketchbook. (I put quotes around “lucky” since the number has never actually been lucky for anything but I call it my lucky number anyway.)

Just like any project that requires tools, measuring, fractions, or spatial relations, building this simple press was not easy for me. First I had to saw the wood. I didn’t want to have to go to Home Depot (ick) to get someone to do it for me I had a piece of fake oak shelving I’d bought but hadn’t used.

So I used my funky little hand saw (that I bought when I became a home owner and thought I should have a basic set of tools in a toolbox “just in case”) to cut the shelf in half into two one0-foot square pieces. It took forever and my cut was wobbly, uneven and made a mess of the veneer.

Then I measured in from each corner one inch and drilled holes, guessing how big they should be. Unfortunately, since my cut wasn’t even, the holes didn’t line up right and they were too small. So when I assembled all the pieces the boards were all tilty and got stuck. I finally got it all apart again and redrilled the holes larger. This solved the problem and the press worked fine.

Like every step in the bookbinding process, I learned something valuable along the way. In this case I learned I should have clamped the two boards together and just drilled right through both of them to make the holes line up.

In my next post I’ll offer some resources for do-it-yourself bookbinding including the tips I learned from my mistakes.